Linear Optimization

The task of optimization is to find the optimal value for a given objective, while satisfying given constraints.

The program determines the optimal solution for a two-variable objective function with linear inequalities as constraints.

Example 1 (Maximization)

A factory produces two different types of cell phones. X units of type A and y units of type B are to be completed daily.

- Constraints:

- The individual departments have the following daily production capacities:

- The assembly line for type A can produce a maximum of 600 units.

x ≤ 600 - The assembly line for type B can produce a maximum of 700 units.

y ≤ 700 - The plastic department can produce a maximum of 750 units. x + y ≤ 750

- The electrical department can produce a maximum of 400 type A units or 1200 type B units or a combination of both.

This means that 1/400 of the total time is required for each of type A and 1/1200 for each of type B.

1/400·x + 1/1200·y ≤ 1 or 3·x + 1·y ≤ 1200;

- The assembly line for type A can produce a maximum of 600 units.

- Objective function:

- How many units of each type must be produced per day in order to obtain maximum profit if the profit for type A is $140 per unit and for type B $80.

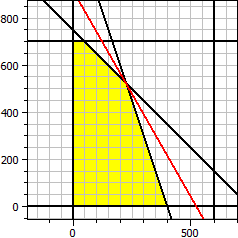

Objective function: ƒ(x,y) = 140·x + 80·y → Maximum Constraints: x ≥ 0 y ≥ 0 x ≤ 600 y ≤ 700 x + y ≤ 750 3·x + y ≤ 1200 Maximum x = 225 y = 525 ƒ(x,y) = 73500

Therefor, the maximum profit of $73500 is achieved if 225 type A and 525 type B units are produced each day.

Example 2 (Minimization)

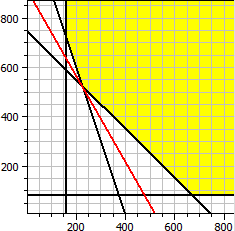

Objective function: ƒ(x,y) = 140·x + 80·y → Minimum Constraints: x ≥ 0 y ≥ 0 x ≥ 160 y ≥ 80 x + y ≥ 750 3 x + y ≥ 1200 Minimum x = 225 y = 525 ƒ(x,y) = 73500

Note:

The conditions x ≥ 0 and y≥ 0 do not need to be entered. They are automatically added.

See also:

Setting the graphicsWikipedia: Linear programming